Cornis Cloud is a platform dedicated to wind turbine inspection.

All your data in one place!

Cornis Cloud is a platform dedicated to wind turbine inspection.

Inspect your turbines with the method of your choice (Cornis' tools or others)

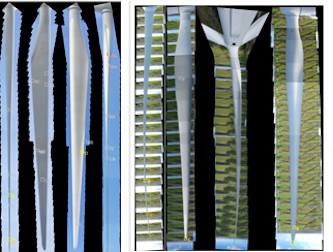

Optimization of the images, stitching and defect detection with AI.

Access to all data and reports on a centralized portal.