Onshore & Offshore Intrablade Inspection

Just like Panoblade, Intrablade is the first step to a standard, precise and cost-efficient blade follow-up over time.

START USING INTRABLADENo more bad inspection

Make onshore and offshore visual wind turbine blade inspections easy to execute, accurate, standardized and cost-efficient.

The right data at the right moment

Allow for the tracking of the blades status over time, no matter the inspection method used nor the supplier involved.

The best use of your people

Differentiate the field work, that can be done by any regular technician, from the expertise work performed right online by experts.

Intrablade is a safer and more accurate way to do internal inspections.

Several turbines a day!

Intrablade is really quick to set up and allows a scan of the internal sides of the blade in a record time: 2 to 3 hrs per turbine when other methods can take a full day.

No technician inside the blade!

Intrablade reduces work in confined space to its minimum. An Intrablade inspection requires only one technician in the hub and another in the nacelle to manipulate the rotor: no one inside the blade!

5 years later you can still compare the inspections.

Our acquisition process is simple and we can train your technicians to use Intrablade on all type of turbines onshore and offshore no matter the model, the size and power.

100% of the inside blade scanned!

The complete inside of the blades is scanned. After the processing, the data is centralized on Cornis Blade Manager, our online platform dedicated to blade data. They remain available at any time.

360° HD pictures!

Intrablade system relies on HD imagery and offers an insight of the blades deeper than any other existing method. All the defects identified online, by our experts or yours, are measured and localized from the hub.

Cornis Artificial Intelligence here to help on expertise!

The identification and analysis of the blade defects is done online on Cornis platform helped by Artificial Intelligence, either by your experts or by ours.

We take care of your data!

All your Panoblade data is integrated and saved into Blade Manager, the online data management platform we give you access to. Following your blades over time is made easy.

How Cornis Blade Inspection Works

Onsite inspections by Cornis' technicians or yours.

Images optimization, defect detection by AI.

AI-results review by a blade expert, reporting and online integration.

We take care of everything

When planning your Panoblade (external) and Intrablade (internal) inspections, Cornis can handle all the steps, onshore or offshore: data acquisition onsite by a Cornis technician + processing and reporting of the data on Cornis web-based platform + online analysis of the defects by a Cornis composite expert.

Learn moreYou internalize.

Train your team and internalize the blade data acquisition process by using your own Cornis inspection system. Cornis will handle the processing and reporting of your data on our platform, no matter the data source. Your data is centralized and easily accessible online for further analysis, either by Cornis experts or by yours.

Learn more

External Inspection

Very few logistics for a consistent, detailed, easy to plan and efficient inspection!

Panoblade system was developed more than 5 years ago and consists of a HD photographic system on a motorized head controlled by a field software we have developed. It is placed right underneath the turbine onshore or on the transition piece offshore and allows for the scan of the full surface of the blades in a record time. Cornis then handles the data processing and reporting on our web platform in order for blade experts to do the analysis right online. Panoblade system quality allows to track sub-millimeters defects. Those defects are systematically measured and localized from the hub.

Internal Inspection

Just like Panoblade, Intrablade is the first step to a standard, precise and cost-efficient blade follow-up over time.

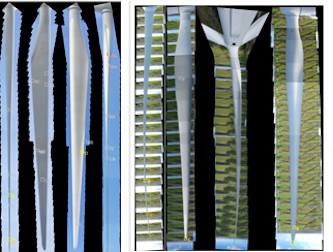

The Intrablade system is a HD photographic system allowing a 360° capture of the internal parts of the blades with no missing points. Deployed into cavities, by technicians trained by Cornis, it allows safe and precise internal inspections.

Cornis has inspected more than 10 000 wind turbines onshore and offshore

Cornis now works in all the continents.

Thanks to our easy to use software and our training programs, everyone can have access to our leading technology.

Each reviewed defect is stored and analysed to enhance A.I. algorithm and experts training.

As a data specialist, Cornis store and secure your data and analyse it thanks to A.I.

Our technicians can inspect up to 12 turbines a day. And we can train you to do the same!

You want to start using our solutions or have some questions? Answer a few short questions and we'll get in touch with you!